Turnkey Solution provider of waste water purification and recycling Vacutherm mastered the art of Industrial waste water (Effluent) purification, separation of dissolved solid matter and up to 99% recycling of purified water of absolutely low TDS in process. This makes industry in category of Zero Liquid Discharge and Almost Zero Fresh water intake for process use.

Waste water Purification is based on Vaporisation and distillation without use of steam, thermic fluid, Electrical heating of any kind of heat source.

Vacutherm uses modern and highly energy efficient Mechanical Vapour Recompression technology for waste water purification, requires only electrical energy for operation. No need of Boiler and cooling and condensing section for heat generation and its dumping.

Benefits

No heat rejection unit

No chemical treatment

No RO/No membrane

No ground water extraction

100% clean water recovery and recycling

Minimal electric power demand

Evaporation at low ΔT

Lowest foot-print area

High quality product

Automated operation

Low capital cost

Minimum operational and maintenance cost

Eco-friendly

Wide applicability

Applications

Waste Water Treatment Industries

Chemical Industries

Textile Industries

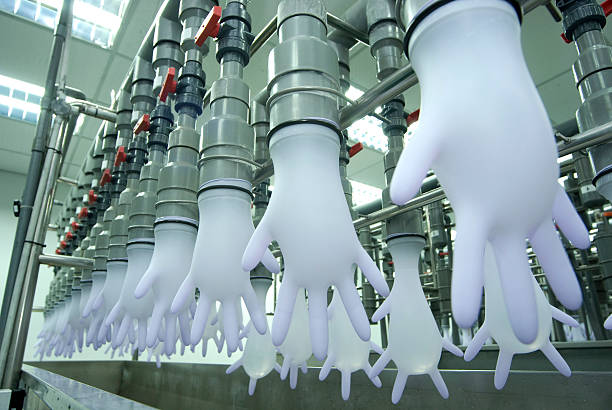

Latex Industries

Process & Allied Industries

Leather Industries

The great explorer of the truth, the master-builder of human happiness no one rejects dislikes avoids pleasure itself because it is pleasure but because know who do not those how to pursue pleasures rationally encounter consequences that are extremely painful desires to obtain.

Read More